To ensure the continued performance and safety of your aircraft exhaust parts and to prevent disasters such as carbon monoxide poisoning, loss of engine power, or fire, it is critical to perform thorough inspections on a regular basis. In this checklist, we'll walk through some key inspection steps to help you effectively ensure your parts are in good, functional condition every time you take to the skies.

Examine the surfaces adjacent to the exhaust system components for telltale signs of exhaust soot. These will reflect leakage points.

Look for gray, red, or black stains at the welds, clamps, flanges, and so on.

Verify that no part of the system is being chafed by the cowling, cables, or other parts. Check the area of the heater for any signs of leaks, as well.

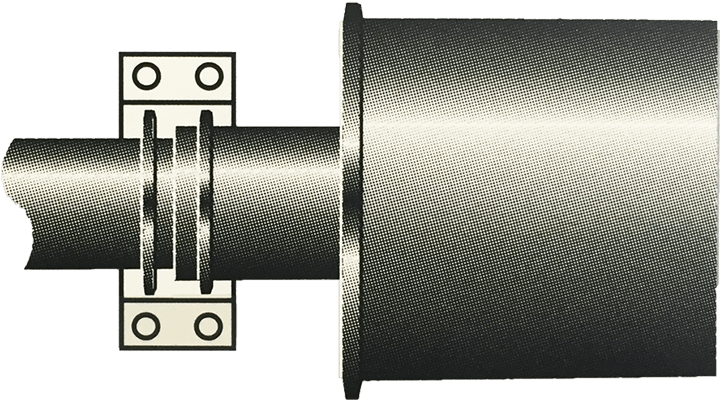

Check for loose connections or binding of slip joints.

Examine any bends and narrow spots for thinning and pitting.

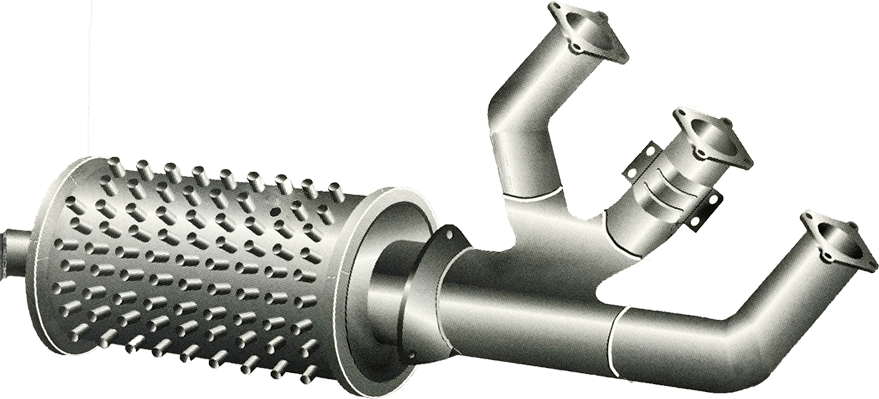

Look for any missing or damaged heat transfer pins or fins, as these can create holes in the exhaust.

Inspect all surfaces for bulging and distortion

Inspect all surfaces for patches of small cracks

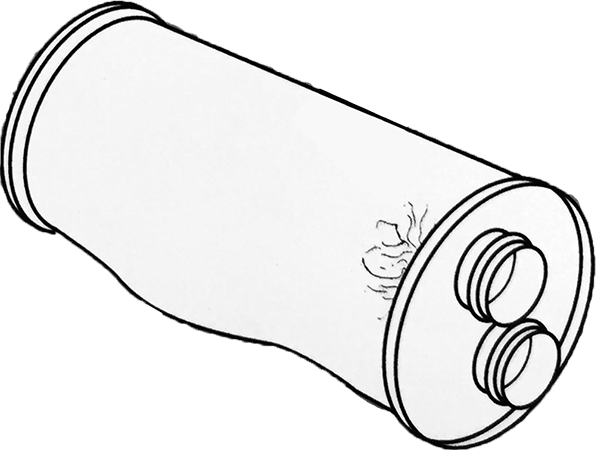

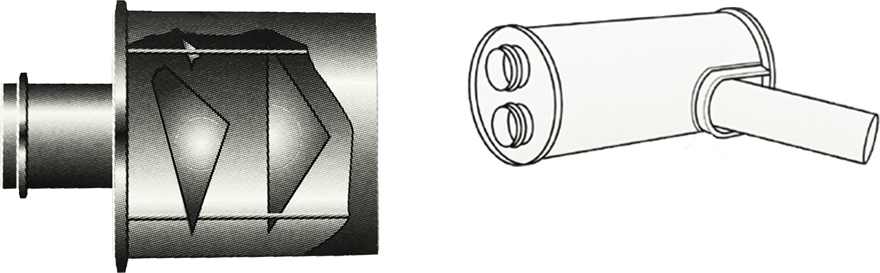

Look inside the mufflers for broken baffles and tubes. These can restrict the outlet and cause power loss.

Carefully inspect all internal surfaces that lie hidden under external gussets or stiffeners. Check for cracked or broken spot welds.

Approximately one-half of all exhaust system failures are traced to cracks or ruptures in the heat exchanger surfaces used for cabin and carburetor air heat sources.

The failures are, for the most part, attributed to thermal and vibration fatigue cracking in the areas of stress concentration.

Only install correct parts and never force-fit. Do not reuse gaskets. Properly align connecting parts.

Tighten nuts evenly to the proper torque value (per OEM specifications).

.png)

.png)

When in Doubt, Call the Industry's Best

If you ever have uncertainties about the airworthiness of an aircraft exhaust part, call a Nicrocraft™ exhaust system specialist at +1 405-672-1361.

Do not attempt to weld-repair damaged parts. It is always best to replace with new parts.

The Industry's Longest Warranty

All Nicrocraft™ parts are covered by our 12-month, unlimited-hours warranty against defects in material and workmanship under conditions of ordinary use and service. Unlike others in the industry, coverage begins from date of installation – not date of purchase. Register your parts today to start taking advantage of the industry's longest warranty.